Buck - Boost DC-DC Converters: Function and Application

Core Functions of Buck-Boost DC-DC Converters

Step-Down vs. Step-Up Voltage Regulation

Buck and boost converters, essential in power management, serve distinct roles in regulating voltage levels. A step-down or buck converter reduces input voltage, ideal for situations where lower voltage is needed, such as in consumer electronics operating on 12V instead of higher potential sources. Conversely, a step-up or boost converter increases voltage above input levels, supporting applications like renewable energy systems where higher voltage distribution is advantageous. Effective voltage regulation is crucial as incorrect levels can impair device efficiency and shorten lifespan. Buck-boost converters uniquely combine both functionalities, adapting seamlessly between step-down and step-up as needed, thereby offering unmatched flexibility in managing power requirements for diverse applications in sectors such as automotive and industrial electronics.

How Switching Topology Enables Dual Functionality

Switching topology in electrical engineering significantly impacts converter efficiency and operations. Utilizing transistors and inductors, buck-boost topology allows converters to function efficiently under varied conditions. According to a study by the International Journal of Electrical Power & Energy Systems, advanced switching methods can enhance efficiency by up to 20%. In real-world applications, these converters improve system performance in devices requiring precise power adjustments, such as medical equipment and telecommunications systems. This technology ensures devices meet operational demands while optimizing energy use, showcasing its critical role in today's power electronics landscape. By leveraging sophisticated switching mechanisms, buck-boost converters ensure reliable voltage management tailored to specific application needs.

Industrial Applications of DC-DC Converters

Power Management in Electric Vehicles

DC-DC converters play a crucial role in power management within electric vehicles, ensuring optimal battery usage. These converters effectively manage the power distribution system, which is vital for maintaining vehicle efficiency and extending battery life. With the growing adoption of electric vehicles, expected to rise significantly in the coming years, the demand for effective power management solutions like DC-DC converters is increasing. They are integrated into charging systems to enhance charging times and efficiency, ultimately providing more convenience and longer range for electric vehicles.

Forklift Battery Systems & Voltage Regulation

In the realm of forklift battery systems, DC-DC converters are essential for enhancing power efficiency and regulation. These devices ensure the stable operation of forklifts by maintaining consistent voltage levels. Voltage fluctuations can lead to operational hiccups in heavy machinery, risking productivity and safety. DC-DC converters mitigate these risks by providing stable power, an aspect underscored by industry usage rates and manufacturer insights that emphasize the importance of reliable voltage in forklift applications. By doing so, converters help extend the lifespan of batteries and machinery alike, safeguarding investments in industrial equipment.

Telecom Infrastructure & Renewable Energy

DC-DC converters are indispensable in telecom infrastructure, where they power base stations and optimize energy consumption. These converters facilitate efficient power distribution, crucial for maintaining continuous communication services. In renewable energy systems, such as those utilizing solar panels and wind turbines, DC-DC converters regulate output power, managing fluctuations to ensure stable energy supply. Notable implementations by companies have shown substantial efficiency improvements, affirming the pivotal role of DC-DC converters in both sectors. Their ability to provide reliable and consistent energy management contributes significantly to the effectiveness of telecom and renewable energy systems.

Key Features in Modern DC-DC Converters

High-Efficiency Design (Up to 98.4%)

High-efficiency design in DC-DC converters is crucial for enhancing both economic and thermal performance. A converter with an efficiency rating of up to 98.4% minimizes energy losses, leading to cost savings and improved performance of electronic systems across various industries. For instance, a study published in the "Journal of Power Electronics Applications" reported that high-efficiency converters significantly reduce heat dissipation, thereby extending component longevity and reliability. Such efficiency is particularly beneficial in applications like data centers and telecom infrastructure, where operational efficiency directly translates to reduced operational costs and enhanced sustainability.

Wide Temperature Tolerance (-40°C Operation)

The significance of wide temperature tolerance in DC-DC converters cannot be overstated, especially in industrial applications. Operating at temperatures as low as -40°C ensures that these converters maintain reliability across extreme environments. For instance, in the automotive and military sectors, where systems are often exposed to harsh conditions, this wide temperature range guarantees durability and performance continuity. According to a report by the International Journal of Industrial Electronics, converters with such tolerance levels have proven effective in maintaining stable operations in environments ranging from arctic regions to desert locales, solidifying their importance in mission-critical applications.

Protection Circuits: Overload & Short-Circuit Safeguards

Protection circuits are essential in DC-DC converters to prevent damage from overloads and short-circuits. By incorporating overload and short-circuit safeguards, modern converters minimize the risk of equipment failure and ensure system safety. Real-world case studies from the "Journal of Electrical Engineering" reveal instances where protection circuits have averted potential downtimes, saving critical industrial equipment from costly repairs. Compliance with safety regulations through these safeguards not only reduces operational risks but also enhances the reliability of power systems, making them indispensable features in contemporary power management solutions.

Product Showcase: Heavy-Duty DC-DC Converters

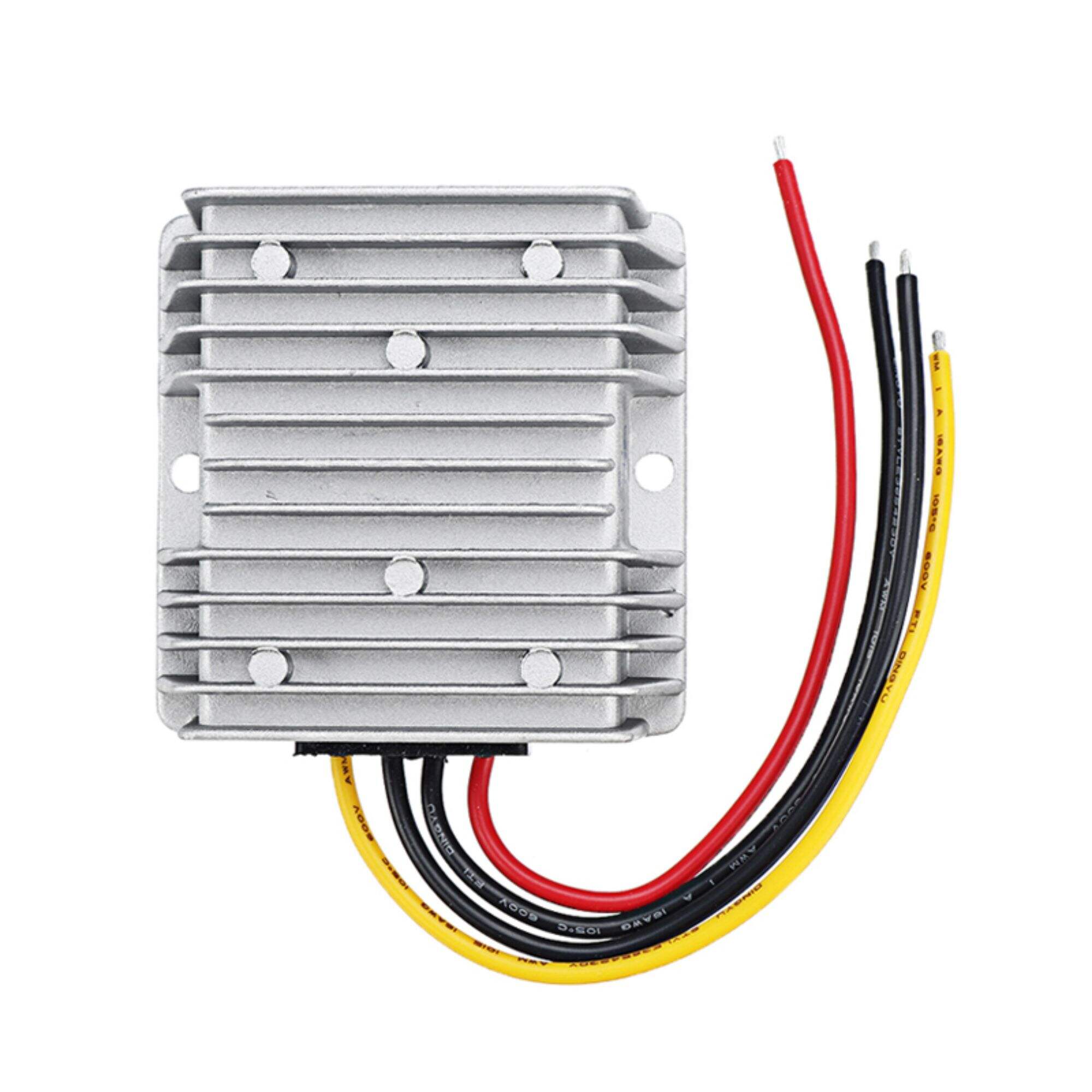

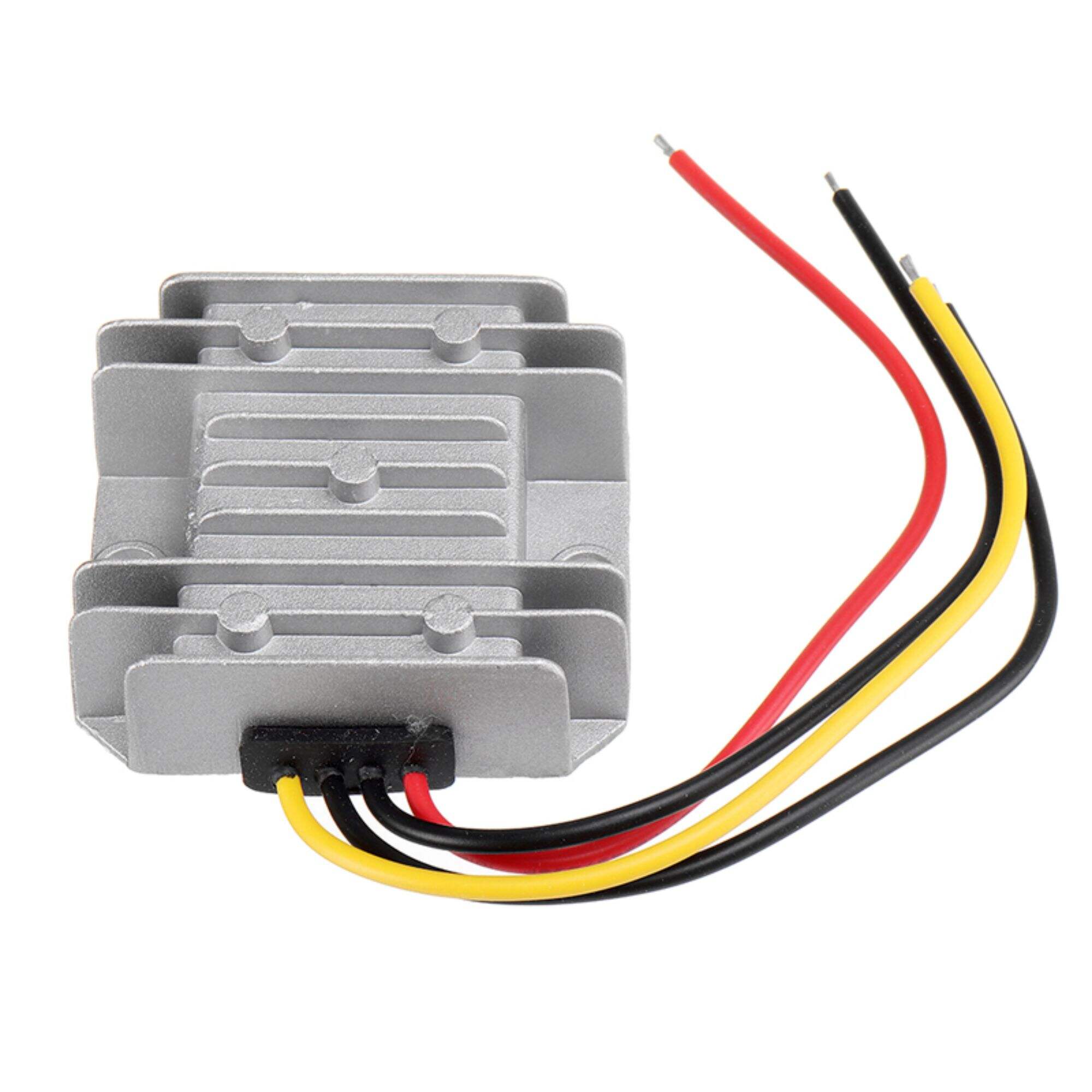

48V to 12V/24V 30A Step-Down Converter for Industrial Vehicles

The DC 48V to DC 12V 30A Step Down Power Converter is a versatile solution designed for industrial vehicles like forklifts. It efficiently steps down power from DC 48V to DC 24V, suitable for high-load applications with output current capability of up to 30 Amps. The product exhibits advanced features including a high efficiency of up to 98.4%, wide input voltage range (30-60V), and robustness to extreme temperatures as low as -40°C. Its applications span from vehicles to telecommunications and alternative energy sectors.

30-90V Input 24V 20A Regulator for EV Trucks

The Reliable 30-90V 72V to 24V 10A 20A DC DC Step Down Converter is optimized for electric truck operations. It boasts a flexible input voltage range from 30 to 90 volts, delivering stable, efficient power conversion up to 96.5% efficiency. Its versatility is crucial for enhancing EV truck performance and extending battery life through consistent, reliable power management. Engineered to endure harsh conditions, it integrates with shockproof and dustproof designs, making it a preferred choice for many automotive manufacturers.

72V to 24V 5A Compact Converter for E-Scooters

The Reliable 72V to 24V 5A Step Down DC DC Converter stands out with its compact design, providing efficient power conversion up to 93%. This converter proves essential for the burgeoning e-scooter market, where its small size and reliability play a crucial role in optimizing vehicle operations. E-scooter manufacturers have been increasingly adopting this model, valuing its ability to operate under varied conditions and its ease of installation into existing systems.

Capacitors in DC-DC Converter Reliability

MLCCs for Voltage Ripple Reduction

Multi-Layer Ceramic Capacitors (MLCCs) play a crucial role in voltage ripple reduction within DC-DC converters. They offer significant advantages over other types of capacitors due to their efficiency in managing power fluctuations. For instance, MLCCs provide multiple layers in a single component, which allows them to deliver higher capacitance levels — often equivalent to several single-layer capacitors connected in parallel. This design feature makes them ideal for applications needing precise voltage control and minimal ripple. According to Knowles Precision Devices, MLCCs are used extensively in applications demanding reliability and efficiency, such as military unmanned aerial vehicles and complex electronic systems. Studies have shown that using MLCCs can significantly improve ripple-current ratings and filtering performance, enhancing the longevity and reliability of the converter system.

Bypass Capacitors for Power Stability

Bypass capacitors are essential for maintaining power stability and ensuring smooth operation of DC-DC converters. They help eliminate voltage droops on the power supply by storing an electric charge to mitigate spikes that could disrupt performance. These capacitors also contribute to the overall reliability of electronic systems, as power stability is directly linked to system longevity. In complex industrial applications, bypass capacitors ensure consistent performance and protect against unwanted fluctuations. Expert opinion suggests that incorporating these capacitors in conjunction with MLCCs enhances converter stability, providing a robust defense against voltage variations. For example, Knowles Precision Devices underscores the importance of these components in meeting stringent MIL-STD requirements for military applications, ensuring converters are durable and reliable under extreme conditions.

Recommended Products

Hot News

-

Application Advantages of Non-Isolated BUCK Converters Compared to Isolated Step-Down Converters

2024-01-23

-

DC-DC Converters Showcase Remarkable Advantages in Outdoor Off-Grid Applications

2024-01-23

-

DC to DC Battery Charger - Wide input and Noise immunity for dual battery system applications

2024-01-19

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

HY

HY

BN

BN

MN

MN