Dc-dc-latauslaite

laitteet ladatetaan tehokkaasti liikkuessa ja varmistetaan keskeytymätön virtalähteen saanti.

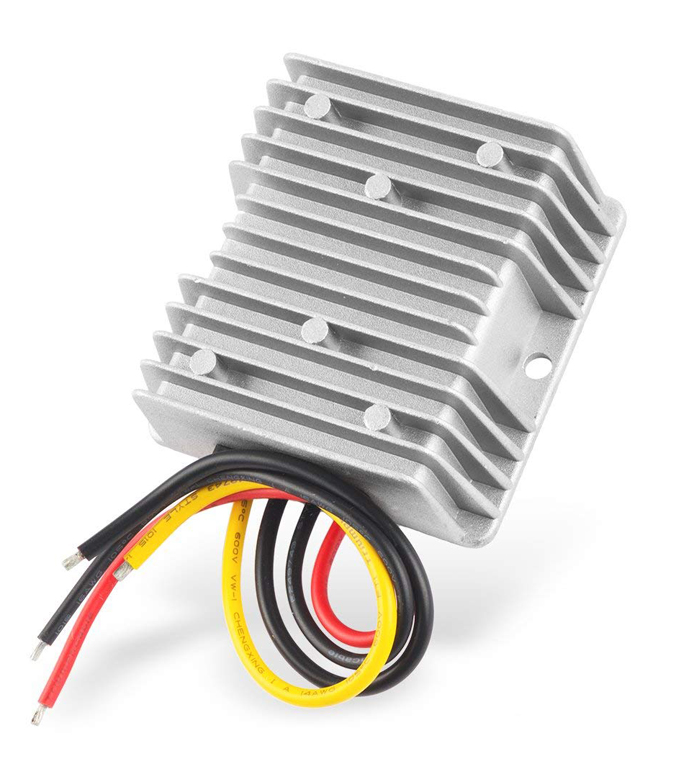

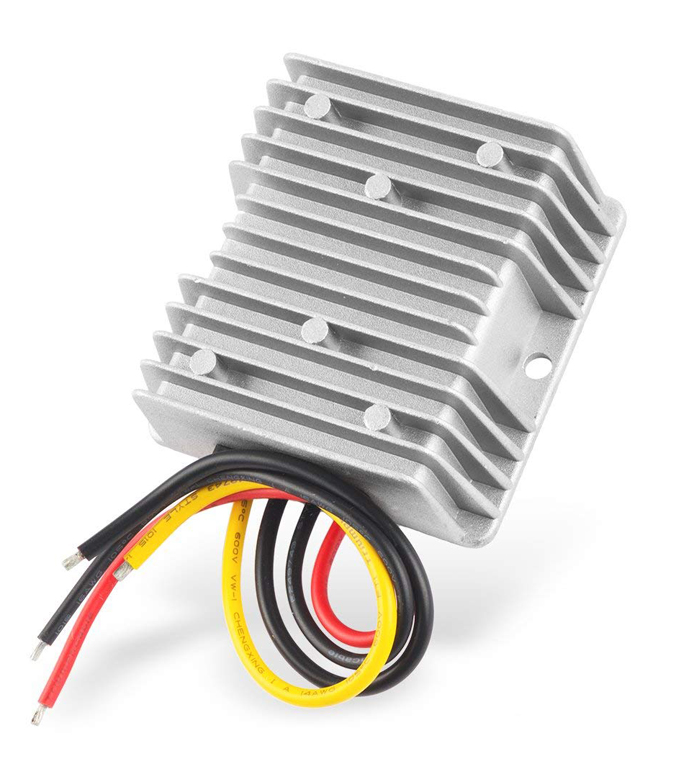

Swengaos DC-DC-muuntajat ovat alan parhaat jännitteen säätelyyn. Ne toimivat tehokkaasti, koska niiden suunnittelu on ainutlaatuinen ja kestävyys vertaansa vailla valmistusprosessin aikana käytettyjen vankojen rakennusmateriaalien ansiosta.

mikä tekee hyvän dc-dc-muuntajan? szwengao: lle se alkaa luovuudesta ja jatkuvasta parantamisesta. Tämä tarkoittaa, että käytetään huipputeknologioita tehoelektroniikassa valmistuksen aikana, jotta nämä laitteet voivat tarjota luotettavaa palvelua tarjoamalla huipputason suorituskykyä, jota mikään muu vastaava tuo

Kaikki virranhallintajärjestelmät pitäisi olla tehokkaita; tavoite, jonka szwengaos DC-muuntaja ylittää. muuntajamme on tehty siten, että ne maksimoivat energian muuntamisen tehokkuuden minimoidessaan tappioita, jotta ne voivat toimia optimaalisesti. lopulta laitteet voisivat toimia tehokkaammin, jos j

Kestävyys on tärkein asia, joka on otettava huomioon kaikissa sähköjärjestelmän hallintajärjestelmissä ja tässä on se, missä szwengaos DC-DC-muuntaja voittaa muut. muuntajamme on valmistettu vahvista materiaaleista ja testattu äärimmäisissä olosuhteissa varmistaakseen, että ne kestävät teollisia ja

Nykypäivän nopeasti muuttuvassa teknologisessa maailmassa on tärkeää pitää jänniteasteet vakaina eri sähkölaitteiden ja järjestelmien sujuvan toiminnan kannalta. szwengaon jännitteiden muuntaja on yksi luotettavimmista ratkaisuista, koska sillä on tarkka jännitevalvonnan kapasiteetti, joka takaa yhdenmukaisen suorit

10 vuotta ammattimainen virtalähteiden valmistaja.

Shenzhen Wengao Electronic Co., ltd pyrkii olemaan paras virtalähteiden ratkaisujen tarjoaja. Luomme ja tuotamme AC-DC-virtalähteitä, DC-DC-muuntajia, akkujen latausjärjestelmää sekä korkean jännitteen virtalähteitä kansainvälisille asiakkaille. Tuotejoukossamme on

laitteet ladatetaan tehokkaasti liikkuessa ja varmistetaan keskeytymätön virtalähteen saanti.

vähentää jänniteasteita turvallisesti ja estää herkkiä laitteita vahingoittumasta.

muuntautuu tehokkaan tehon, mikä mahdollistaa laitteiden välisen saumattoman yhteensopivuuden.

ylläpitää vakiota jännitteen tuottoa, suojaa elektroniikkaa vaihtelulta.

JTS-JTS-muuntaja voi ladata tasaisella 30 a:n nopeudella, mikä takaa tehokkaan laadun erilaisiin sovelluksiin.

Tämä laite on valmistettu erityisesti AGM-, LIFEPO4 ja LIMN2O4 -akkujen käyttöön, jotta se voi toimia tehokkaasti niiden kanssa ja olla myös suorituskykyisesti yhteensopiva.

Tämän muuntajan käyttökelpoinen sisääntulojännittealue on 10-36 voltia.

Kyllä, sillä on matala jännitys (lv), yli lämpötila (ot), yli virta vakiovakuutuksessa (oc) ja lyhytpiiri suoja, joka takaa järjestelmän turvallisuuden.

Kyllä, kauko-käyttö on valinnaista, mikä tekee käytöstä ja hallinnasta helpompaa.

se on suunniteltu kestämään äärimmäisiä olosuhteita, joten se on vedenpitävä, pöly- ja iskuvarma ja siten soveltuu monenlaisiin sovelluksiin.